Capabilities

Materials Capabilities:

- Aluminum Oxide

- Aluminum Nitride

- Carbide (CVD, HP, RBSC)

- Fused Quartz

- Fused Silica

- Silicon Nitride (SSN, SRBSN, RBSN)

- Hi-Purity Glass

- Ytrria

- Zirconia (PSZ, TTZ)

| Capabilities | Finished | Standard |

|---|---|---|

| Flatness (as ground) | .0001”/” | .001”/” |

| Flatness (mechanical polish) | .000002” | – – – – – – |

| Straightness | .0002”/” | .001”/’ |

| Circularity | .0001”/” | .001”/’ |

| Cylindricity | .0001”/” | .001”/’ |

| Perpindicularity | .0001”/” | .001”/’ |

| Squareness | 0:00.30o | 0:30.00o |

| Angularity | 0:00.30o | 0:30.00o |

| Parallelism | .00005”/” | .0005”/” |

| Surface Roughness (as ground) | – – – – – – | 32u” |

| Surface Roughness (manual polish) | 8u” | – – – – – – |

| Surface Roughness (mechanical polish) | >2u” | – – – – – – |

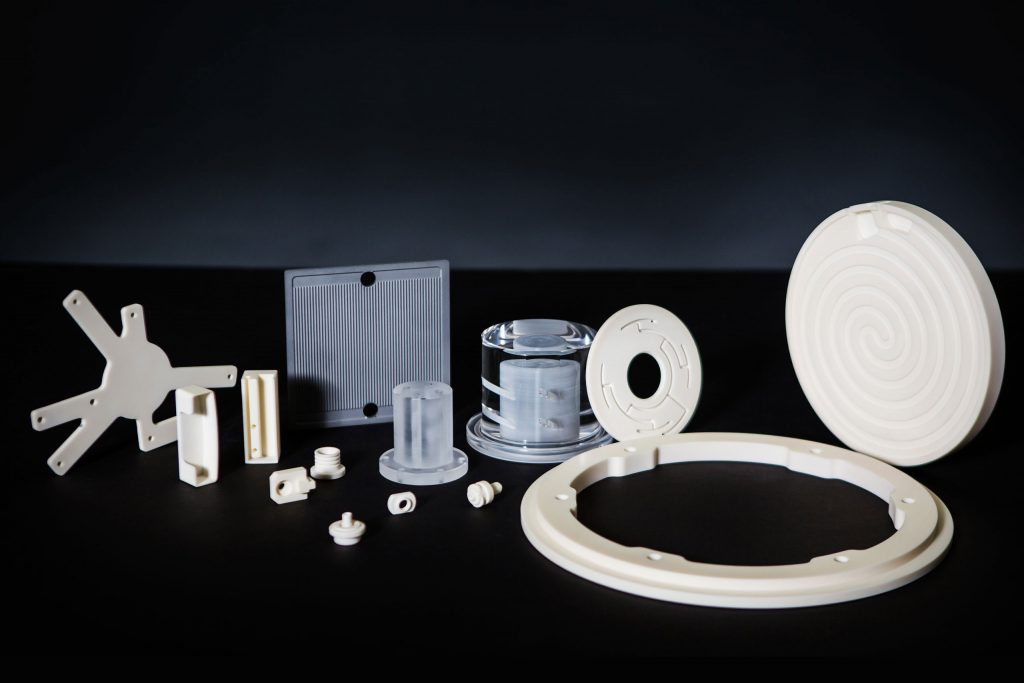

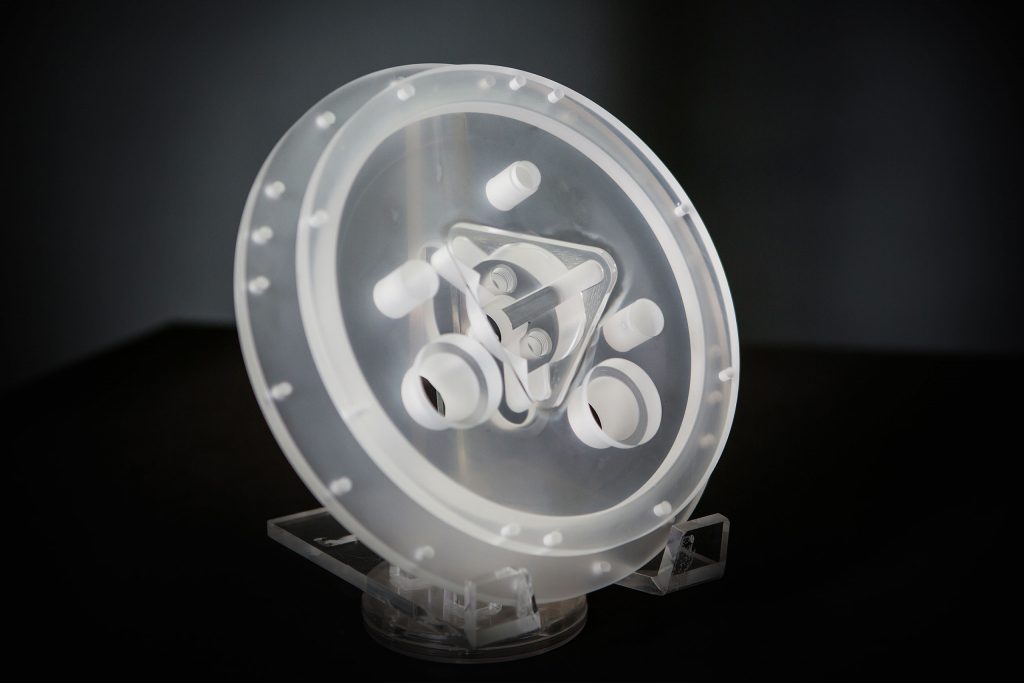

Ceramics & Quartz Machining

Advanced Industrial Ceramics performs precision machining and grinding services on ceramics and quartz. Materials are processed, measured and cleaned with state-of-the-art equipment by highly trained professionals. All parts are designed and fabricated to the customer’s specifications. We perform the following services on ceramics and quartz materials:

CNC Machining – Lathe, Mill, Surface, Ultra Sonic

Automated Machining – Blanchard, Lathe, Mill, Surface, Universal grinding

Manual Machining – Blanchard, Lap/Polish, Lathe, Mill, Surface grinding, Lapping/Polishing

Ceramics and Quartz Machining – Rapid prototyping with 1.5-3 week delivery Subcontract Grinding Prototype and Quick Turn NPI and First Article Production Small Run production

Materials

- Aluminum Oxide

- Aluminum Nitride

- Carbide (CVD, HP, RBSC)

- Fused Quartz

- Fused Silica

- Silicon Nitride (SSN, SRBSN, RBSN)

- Hi-Purity Glass

- Ytrria

- Zirconia (PSZ, TTZ)

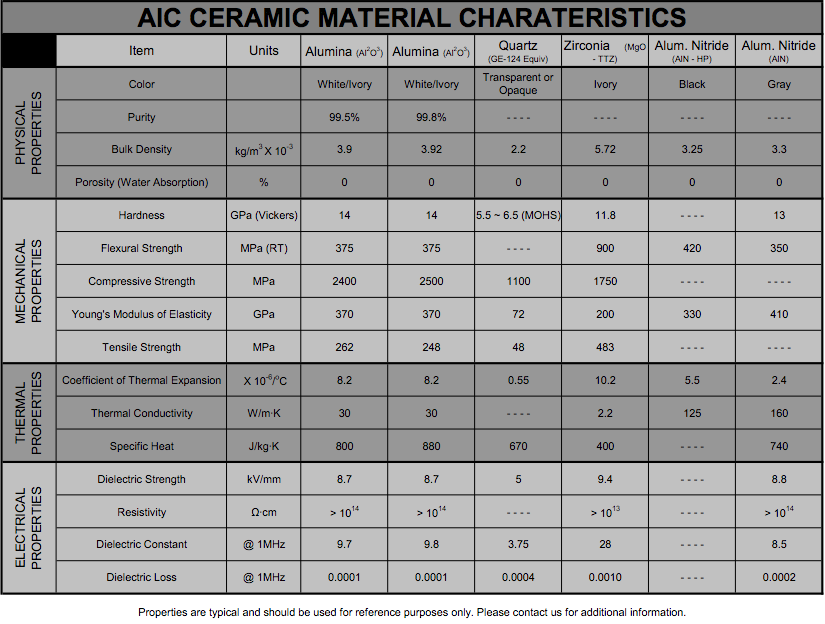

Materials Offered

- Aluminum Oxide

- Fused Quartz (Transparent or Opaque)

- luminum Nitride

- Silicon Carbide (CVD, HP, RBSC)

- Silicon Nitride (SSN, RBSN, HPSN)

- Zirconium Oxide

- Boron Carbide

- Single Crystal Silicon

- Sapphire

- Macor® Machinable Glass Ceramic

Secondary Services

- Lapping/Polishing

- Chemical Cleaning for clean room use

- Quartz Welding

- Fire Polish and Annealing

- Clean Room Packaging

- Laser marking

- Inspection

- Texturizing (media blast)